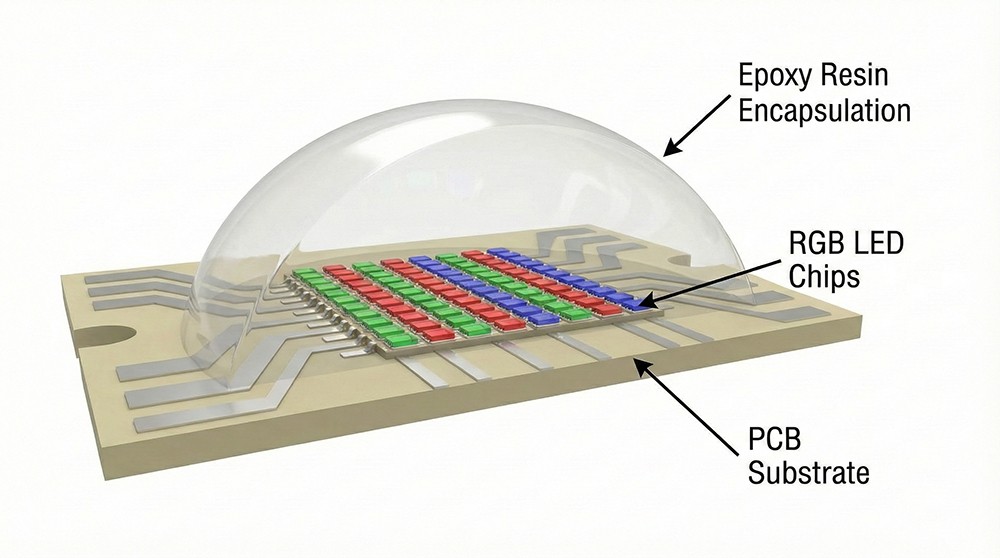

COB (Chip on Board) technology is a manufacturing process where Red, Green, and Blue (RGB) light-emitting diode chips are encapsulated directly onto the printed circuit board (PCB).

Unlike traditional packaging methods, COB technology eliminates the need for independent lamp bead brackets (or legs), integrating the bare chips directly onto the substrate. This process not only allows for higher chip density but also creates a flat, uniform light-emitting surface. Because the RGB chips are integrated so closely together, COB displays can achieve a wider color gamut, thereby reproducing more realistic images.

Simply put, within the same display area, COB technology can accommodate significantly more LED chips than traditional technologies (such as SMD or DIP), resulting in a massive improvement in display resolution.

Differences Between COB and SMD Packaging Technologies

Before COB technology became popular, LED displays mainly relied on SMD (Surface Mounted Diode) and DIP (Dual in-line Package) technologies. Among them, SMD long occupied the mainstream position due to its relatively high density.

1. Structure and Connection Method

- SMD Technology: LED components are mounted on the PCB surface via wire bonding and fixed using a soldering machine. While this method is mature, improper control of the soldering process (such as weak or excessive soldering) can lead to connection failures. Additionally, SMD components protrude from the circuit board surface, making them vulnerable to physical impact or environmental factors like moisture.

- COB Technology: Chips are bonded directly to the circuit board using adhesives, eliminating the need for metal wires. This connection method is more stable and greatly reduces the risk of failure caused by soldering issues.

2. Pixel Pitch and Size

- SMD Technology: Usually limited by component size (generally larger than 0.5 mm), making it difficult to achieve extremely small pitches.

- COB Technology: Can handle micron-level chips without needing space for wires. This allows for a tighter Pixel Pitch, which is crucial for manufacturing high-resolution (e.g., 4K, 8K) Micro LED displays.

Four Core Advantages of COB LED Technology

Now that we understand the basic principles of COB, let’s look at the revolutionary improvements it brings to practical applications:

1. Extreme Pixel Pitch and Resolution

Pixel pitch determines the fineness of a display. Because COB technology eliminates brackets and pins, pixel points can be packed very tightly. A smaller pixel pitch means higher pixel density, enabling COB displays to easily achieve 4K or even higher resolutions.

For the viewer, this means that even when watching the screen from a close distance, there is almost no visible “pixelation” (screen door effect), resulting in a much smoother and more detailed visual experience.

2. Superior Reliability and Protection

Traditional SMD screens are prone to “dead pixels” caused by bumps and are sensitive to environmental moisture. COB technology achieves a leap in reliability:

-

- Collision Resistance: The surface of a COB screen is typically covered with a layer of epoxy resin. The surface is flat and smooth, offering extremely strong protection against impact.

- Dust and Water Resistance: Thanks to the overall encapsulation process, the protection rating of COB displays can typically reach IP54 (compared to SMD, which is usually only IP20 or IP30), effectively resisting dust and moisture intrusion.

- Better Heat Dissipation: Direct encapsulation on the PCB reduces thermal resistance, resulting in better heat dissipation and extending the lifespan of the screen.

3. Higher Energy Efficiency

For large display equipment that needs to run 24/7, energy consumption is a huge cost factor. COB LED technology offers higher luminous efficiency and lower heat loss compared to SMD technology. Over long-term use, COB displays can significantly reduce operating costs, making them more energy-saving and environmentally friendly.

4. Upgraded Visual Experience

COB technology is not just “durable”; its image quality performance is also superior:

- Ultra-Wide Viewing Angle: Utilizing Flip Chip technology, COB screens can achieve a viewing angle of up to 170 degrees, maintaining consistent color accuracy regardless of the angle from which it is viewed.

- High Contrast: COB technology can achieve deeper blacks and higher brightness, significantly boosting contrast ratios. This makes it ideal for venues with extremely high image quality requirements, such as architectural design studios, high-end conference rooms, broadcasting studios, and medical research facilities.

Final Thoughts

COB LED technology represents the latest breakthrough in LED packaging processes. By shortening pixel pitch, enhancing protection ratings, reducing energy consumption, and optimizing visual effects, it is redefining the standards for high-end displays. Whether for commercial displays, command centers, or high-end home cinemas, COB technology has demonstrated its immense potential as the “future of display technology.”